Inceptio, a Chinese developer of autonomous driving technologies for heavy-duty trucks, recently gave AAVI an exclusive insight into how it continues to help Deppon Express improve efficiency on its regular Shanghai-Jinan operational route.

Deppon began trial operations of Inceptio’s technology in September 2021 and has continued to use it ever since. This particular case study follows a recent trip in February, and shows how Inceptio’s technology helped a single driver complete a nearly 13-hour run from Shanghai through rain, fog and strong winds.

On the road

On a cold February morning in Shanghai, driver Shuangying Li starts the engine of a 6X4 heavy-duty truck. It is 7:58am as he navigates the truck out of a Deppon Express depot on the outskirts of Shanghai. His destination is Jinan, nearly 900km to the northwest along China’s eastern seaboard.

Li has been driving heavy-duty trucks for 12 years. Throughout his career, he has always completed trips of this length in tandem with a second driver, alternating shifts. Today, however, he is alone in the cab. His heavy-duty truck, a Dongfeng Tianlong 6×4 tractor, is equipped with the Inceptio Autonomous Driving System (ADS). When the truck arrives in Jinan shortly before 9:00pm this evening, Inceptio’s state-of-the-art hardware and software system will have operated it for almost 98% of the total mileage.

At 8:15am, Li merges the truck onto the northbound lanes of the six-lane G15 Expressway. At this point, he activates the Inceptio ADS. The system takes charge of the truck, and Li relaxes his hands from the controls. The Inceptio system keeps the truck in its lane and observes a safe distance from surrounding vehicles. If any object on the road gets close to the truck, a collision warning will sound. On average, Inceptio-powered trucks record 0.1 collision warnings per 100km, which is 98% fewer than human-operated trucks, according to a study by Chinese insurer CPIC.

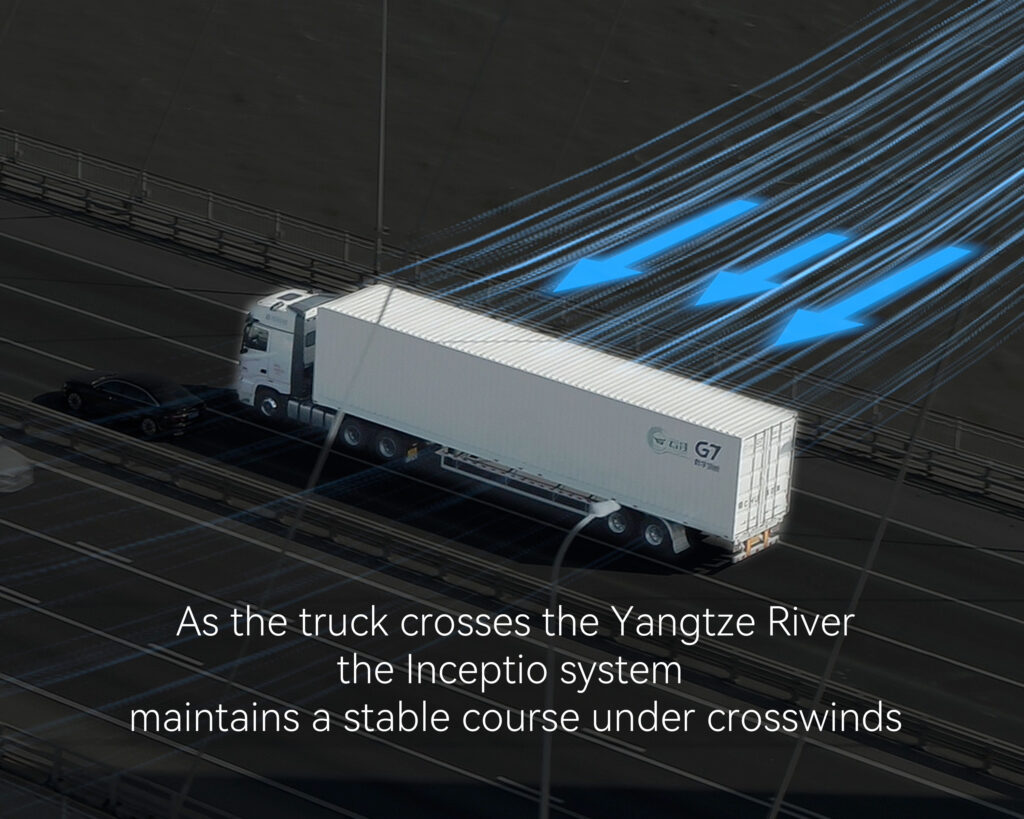

At around 10:00am, the highway takes a 90° turn toward the Yangtze River and the world’s seventh-tallest bridge comes into view. Ahead lies the Sutong Bridge, which, at over 1km in length, was the world’s longest cable-stayed bridge upon its completion in 2008. As the truck crosses the river, the system’s robust adaptive lateral control algorithm detects incoming crosswinds enabling the truck to maintain a stable course before Li takes control of the vehicle. Ten minutes later, the truck has passed onto the north side of the Yangtze, and the Inceptio system is back in control.

Around three and a half hours into the trip, Li stops the truck at a service area. Throughout the journey, Inceptio’s software prioritizes fuel efficiency in its driving decisions, resulting in as much as 10% less fuel consumption than even the most efficient and experienced human drivers in the fleet, according to the company. On a journey of this length, that translates to hundreds of RMB of savings at the pump.

100% coverage

Later in the afternoon, the truck has traversed the length of Jiangsu Province and the Inceptio system navigates the complex interchange from the G15 onto the G25 toward Jinan. Li is leaving behind the flatlands of coastal Jiangsu for the hilly Shandong peninsula. Inceptio says features from its ADS can be activated in any part of the country, with 100% coverage of China’s line haul road network. Commercial drivers like Li are already regularly operating the Inceptio system along 81% of that network. Given the wide range of geographic features across China’s vast expanse, the Inceptio system can handle just about any terrain.

By early evening, the truck is approaching Jinan through rain and fog. The ADS remains engaged through the 3km-long Qinglonggu Tunnel, keeping the truck tightly within its lane despite the lack of wireless connectivity. The truck’s perception capabilities and inertial measurement unit (IMU) and wheel sensors enable it to maintain accurate positioning in long tunnels with no signal. This capability is crucial in China’s many mountainous regions.

As the truck finally reaches Jinan, Li disengages the ADS and exits the expressway, driving just a little further to the Deppon Express facility where his cargo will be unloaded. In all, the trip has lasted 12 hours and 51 minutes, covered 896km, and used 32.36 liters of fuel with a full load, with Inceptio’s ADS engaged for 97.71% of the mileage.

Despite the extreme length of the journey, Li’s Observed Rate of Drowsiness, a metric used to measure drivers’ alertness, is at a low level. Li has been able to keep his body relaxed for most of the trip, and has been required to make few driving decisions. Academic studies have shown that Inceptio truck operators experience 35% less physiological fatigue and 11% less psychological fatigue than manual truck drivers.

Li’s trip is neither unique nor experimental. It is one of more than 50,000 trips that have been made on trucks featuring Inceptio’s ADS. More than 100 freight and logistics companies, including Li’s employer, Deppon Express, have used the company’s technology along 340 different routes across China. Inceptio says this represents the most extensive commercial implementation of autonomous driving technology for heavy-duty trucks anywhere in the world and adds that, to date, Inceptio-powered trucks have safely traveled more than 80 million kilometers.

Li retires for some well-earned rest. It has been a long day, but he will soon be ready to do it again – with the Inceptio system as his co-pilot.

Technology at a glance

Inceptio’s proprietary full-stack autonomous driving system, ‘Xuanyuan’ in Chinese or ‘Inceptio Autonomous Driving System’ in English, includes algorithms, software architecture, a computing platform and a drive-by-wire chassis.

Algorithms

- ULRS – Ultra-Long-Range Sensing with 3D perception error <5% at 1,000m.

- HPLS – High Precision Lateral Sensing with lateral accuracy 54% higher than the industry average.

- ARC 2.0 – Adaptive Robust Control against varying load and flexible link between tractor unit and trailer with control error of <8cm.

- FEAD 2.0 – Multi-Time-Scale Fuel Saving System that enables drivers to save more fuel than skilled drivers, driven by a velocity optimization strategy based on massive operational data.

Driving Control Unit

- ADCU Gen1 with computing power of 245 TOPS, power efficiency of 1.53 TOPS/W and automotive grade redundancy.

- ADCU Gen2 with computing power of 262 KDMIPS + 256 TOPS, scalable architecture that supports >1,000 TOPS and time synchronization of <30ns

Vehicles and clients

Inceptio currently has two manufacturing partners — Dongfeng Commercial Vehicle and China National Heavy Duty Truck Group — to develop its rigs. Clients include Nestle, Budweiser and large Chinese freight companies like ZT Freight and Deppon Express.

Further information can also be found at: https://en.inceptio.ai/technology