Veoneer is using a new OEM-compliant, parallel flash solution from b-plus automotive as a great time saver in ECU development.

In the highly dynamic environment of production and development of control units fitted in vehicles, it is necessary to be able to react quickly and flexibly to software updates from an OEM. In a Tier 1 environment, this includes, for example, the late receipt of software updates during the production phase.

One challenge is to update large quantities of ECUs to the latest software version without incurring high additional costs. In addition, there are strict time limits for the re-flashing of ECUs in high production quantities, which are difficult to meet, especially with large production quantities.

GiraBITE – a new tool from b-plus automotive – now offers a solution for flashing up to 40 control units in parallel by parallelizing the UDS download as a time machine, with potential time savings of up to 4,000%. Veoneer is one of the first customers to rely on the solution, and describes the advantages it offers from the perspective of an ECU manufacturer, below.

Parallel flashing made easy

It’s a familiar problem: production is working under high pressure, but the software on the produced control units is already outdated due to new customer features. A quick update would often mean opening the housings, which would require more time and money. So how could a Tier1 deal with this conflict situation? In order to avoid opening the hardware, the use of an OEM flash process via the vehicle interface is obvious. However, these flashing tools are not necessarily available in production. In addition, existing tools can often only update a single ECU at the same time and do not allow parallel flashing of several ECUs. So what can you do to meet delivery times anyway?

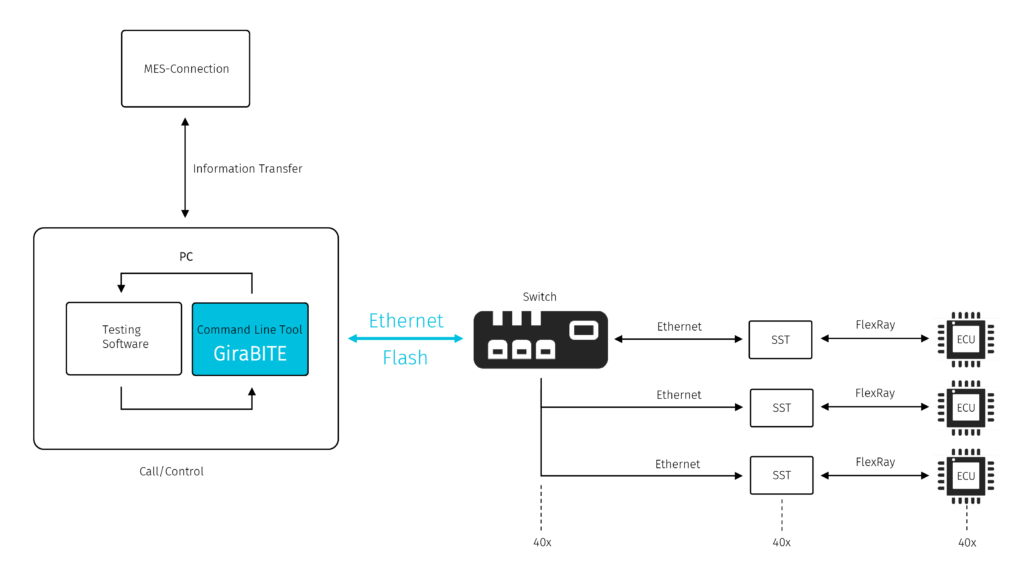

For this problem, b-plus automotive GmbH has extended the established developer flash tool ‘GiraBITE’ by the ‘Multi Instance License’, which is extremely relevant for ECU development. This makes it possible for manufacturers to flash up to 40 ECUs in parallel and 100% OEM-compliant via the vehicle interface with only one computer.

GiraBITE is a hardware-independent UDS flash tool for ECUs, which can be used along the entire process for the development, testing, production and diagnosis of ECUs, according to b-plus automotive. Almost any number of ECUs can be flashed simultaneously with GiraBITE, which represents an enormous potential for time savings. Via a command line, the flash processes can be additionally automated and thus further simplify the flashing of ECUs.

In addition, GiraBITE provides transparency about the flash status and the process progress. Due to its flexible and fast adaptation to customer-specific specifications and workflows, as well as easy integration into existing customer systems, GiraBITE was able to be used immediately as a solution at Veoneer, contributing to the rapid updating of the software status on the already produced ECUs.

GiraBITE can also used for remote updates of control unit software in prototype vehicles or at the lab bench to avoid opening the housing.

Driver assistance control units

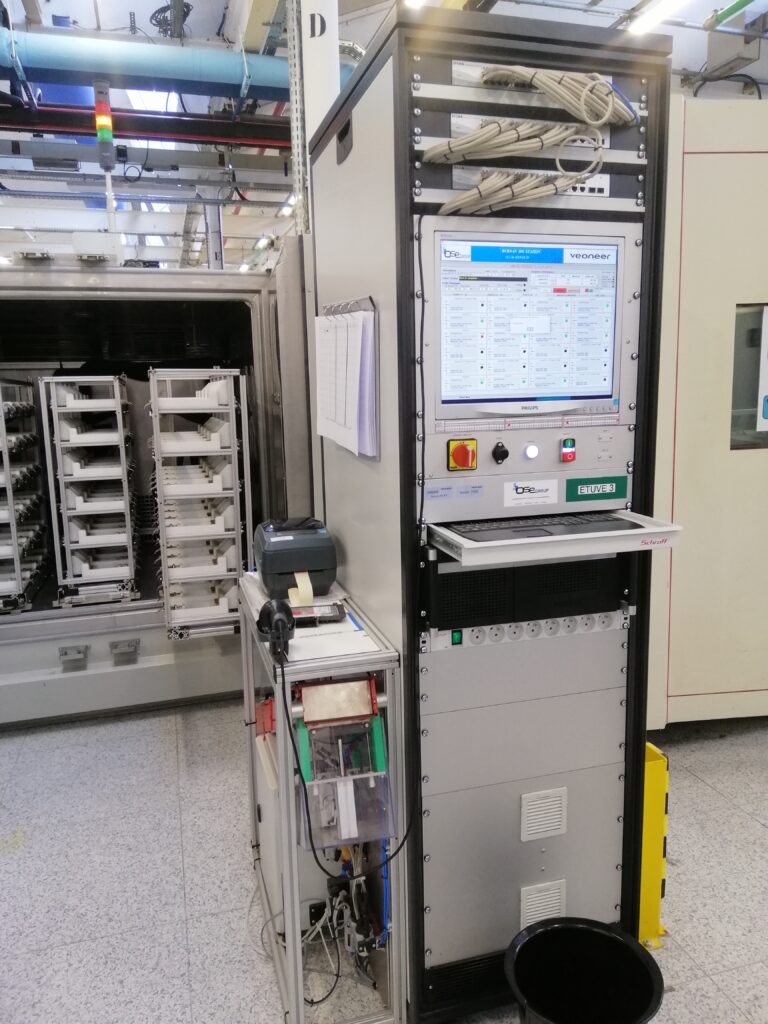

Veoneer is one of the first customers to use GiraBITE. The Swedish company offers technologies for the automotive industry, including the development of driver assistance control units. Especially in this highly dynamic environment, the software is constantly being further developed, even during test and validation phases. Outdated software on ECUs often leads to delays in the production process. In the Veoneer project, a process delay of this kind meant that compliance with the deadline for delivery of their ECUs was at risk. With the help of GiraBITE, this was avoided and the delivery deadline met.

The time-consuming and cost-intensive updating of the software on control units and the associated opening of the housing and subsequent feeding into the production line was not possible for Veoneer due to capacity reasons. It was necessary to flash thousands of ECUs already in stock with an average flash duration of approximately 15 minutes in a very short

time with software updates. Re-flashing with standard tools was therefore out of the question for time and cost reasons. Veoneer therefore looked for solutions with existing tools.

Since Veoneer and b-plus automotive had already carried out several successful projects together in the past, a MES connection was developed for the existing, powerful flashing tool GiraBITE (MES – Manufacturing Execution System). This ensured GiraBITE could be directly integrated into the manufacturing software and the required traceability could be guaranteed. The specified time limit of 15 minutes for updating the control units could even be undercut by using the b-plus automotive tool. The on-time delivery of the ECUs to the OEM was thus ensured. After the successful end of the project, the flash tool is still used by both project participants, Veoneer and the OEM

Flexible connection and integration

The above-mentioned flexible connection of GiraBITE to the specific control unit behavior at Veoneer was only possible due to specific features of the product, according to the German software specialist. These include the large variety of supported input formats, such as ODX Flash, Motorola S-Record and Intel-Hex, as well as a wide range of bus technologies such as CAN, FlexRay, Ethernet, etc. Furthermore, GiraBITE supports a wide range of different manufacturers of CAN and FlexRay interfaces. In combination with good security mechanisms, such as Seed & Keed calculation, checksum calculation and signature calculation, integration of GiraBITE into production software can be done without any problems and without interrupting running production.