Automotive lidar manufacturer RoboSense has obtained IATF 16949 certification, allowing it to work with automotive customers.

Developed by the International Automotive Task Force (IATF) and submitted to the International Organization for Standardization, IATF 16949 is the most widely used quality management standard for the industry.

Dr Leilei Shinohara, co-partner and vice president of RoboSense, said, “IATF 16949 requires extremely high production consistency, and emphasizes various product reliability metrics. It recognizes the RoboSense design, research and development, and production processes. It also indicates that RoboSense has achieved a new milestone of complete readiness for serial mass production of automotive lidars, including the latest solid-state smart lidar RS-LiDAR-M1.”

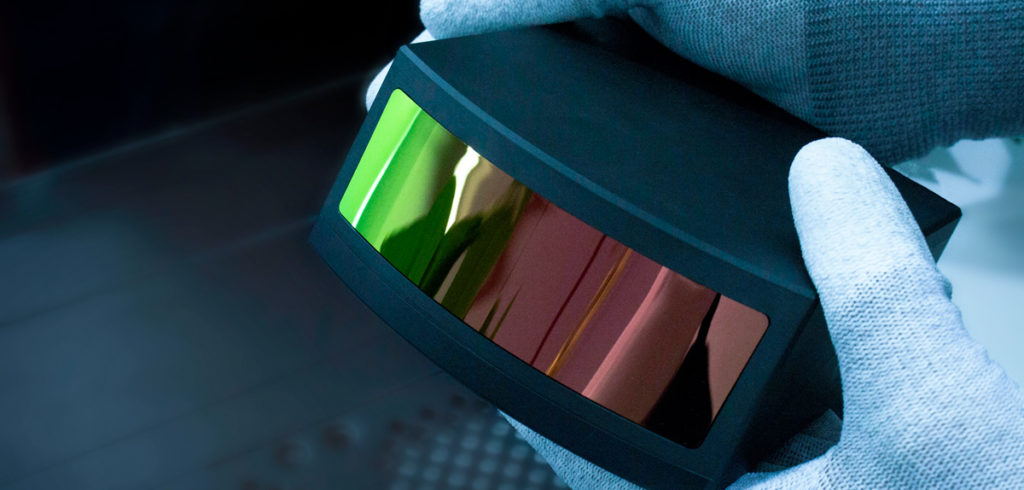

The 125-layer equivalent RS-LiDAR-M1 was officially released in January 2020 as the world’s first MEMS lidar to obtain IATF 16949 for its production line.

During production, RoboSense implemented IATF 16949 quality management and ISO26252 functional safety standards.

Combining ISO16750 test requirement and other automotive-grade reliability specifications with these systems, the accuracy of the RS-LiDAR-M1 can be verified.

MEMS mirror is the core component in RS-LiDAR-M1 with 10 test groups being designed cover factors such as temperature, humidity, packaging process, electromagnetic compatibility, mechanical vibration and shock, and aging.

The test time has exceeded 100,000 hours and the longest-running prototype has been tested for more than 300 days with no degradation.

In Vienna, Austria, the RS-LiDAR-M1 was tested for rain and fog under different light and wind speeds.

The tests proved that RS-LiDAR-M1 met required standards and the final mass-produced product will adapt to all climate and working conditions.