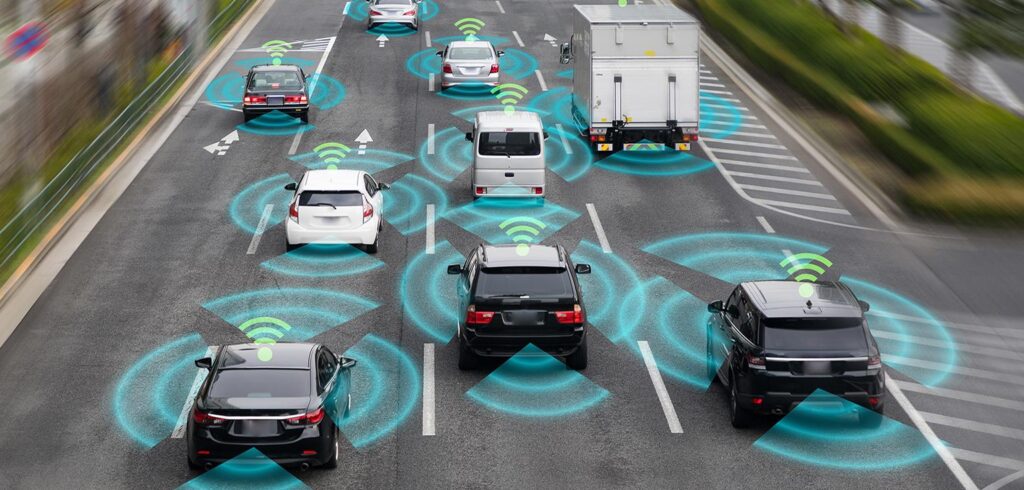

With the ever-advancing development of AD and ADAS systems, automotive OEMs and suppliers require high-performance materials that are compatible with the capabilities of today’s higher-frequency (>75GHz), millimeter-wave (mmWave) radar units.

To help meet this need, plastics supplier SABIC (Saudi Basic Industries Corporation) is launching two new materials, the LNP Thermocomp WFC06I and WFC06IXP compounds, which it has developed specifically for the front and back enclosure covers (respectively) of next-generation radar units.

The company claims the new glass fiber-reinforced polybutylene terephthalate (PBT) grades offer a very low dissipation factor (Df) and dielectric constant (Dk) to help support the transmission of higher-frequency radar signals. They also feature super-low warpage that allows designers to potentially create new, thinner covers to further improve signal transmission.

Additionally, the new products can contribute to efficient radar unit assembly by supporting high-speed, high-precision laser welding. In fact, the LNP Thermocomp WFC06I compound provides excellent laser transmission performance among PBT materials currently available.

“Advancements in ADAS are accelerating rapidly as the automotive industry develops new vehicle technologies aimed at alleviating traffic congestion and improving safety in expanding urban areas,” said Joshua Chiaw, director, business management, LNP & NORYL, specialties, SABIC.

“SABIC is aggressively developing new materials to help ADAS designers achieve goals related to size and weight reduction, signal transmission accuracy and reliability improvements, and seamless integration with the vehicle. We work closely with companies at all levels of the ADAS value chain to understand fast-changing and demanding requirements and deliver tailored, high-performance material solutions that address them.”

Many ADAS designers are adopting higher frequency mmWave radar technology because its improved image resolution and greater range can enable safer driving under a variety of conditions. However, frequencies in the 76-81GHz band present greater transmission challenges compared with lower frequencies. To improve wave transmission, radar covers require very low Df and Dk, thinner walls and a simplified design without support structures. Incumbent glass-filled PBT materials typically do not meet these transmission optimization requirements; for example, they have a Df performance that is greater than 0.01. Also, as semi-crystalline polymers, they have a high tendency to warp when used in thin-wall parts without support structures, potentially leading to part failure during assembly, transport and use.

SABIC states that the compounds surpass incumbent PBT compounds in Df/Dk performance and warpage control and can reduce attenuation of electro-magnetic waves passing through the radar covers to help improve image resolution and range. They also enhance transmission and minimize side cones of the signal beam for improved image quality. Furthermore, the company notes its compounds provide higher ductility for improved impact resistance, and equivalent moisture and chemical resistance versus incumbent PBT materials.