AEye Inc has set a new benchmark for lidar capabilities during performance specification tests carried out on the runway of a Californian airport by VSI Labs, a leading independent automated vehicle technology evaluator and advisor.

The tests were designed to validate the performance of AEye’s iDAR and 4Sight M sensor, which was released in August 2020. AEye’s software-definable iDAR (Intelligent Detection and Ranging) platform combines solid-state active lidar, an optionally fused low-light HD camera, and integrated deterministic artificial intelligence to capture more intelligent information with less data, enabling faster, more accurate, and more reliable perception.

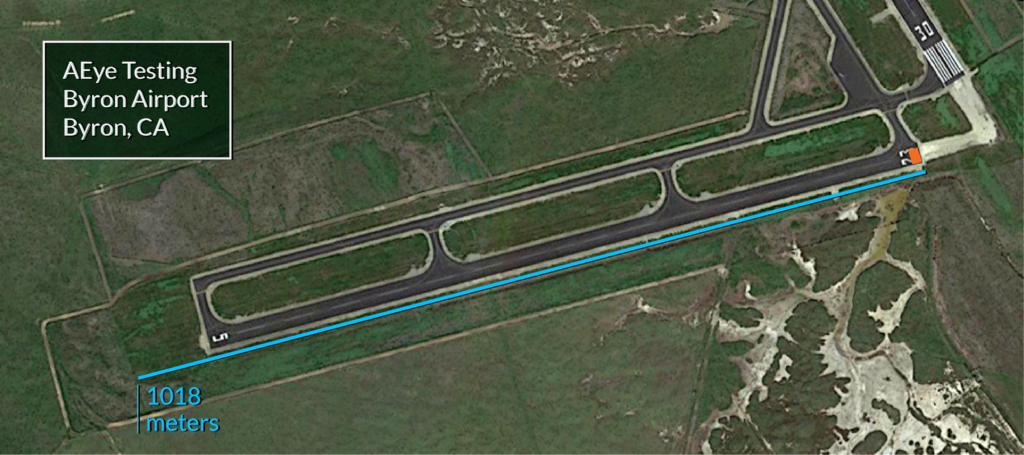

VSI and AEye identified metrics to be tested and jointly developed specific methodology for the collection and protocols on retention and transfer of data prior to testing. The execution was then monitored live by VSI Labs. The tests were conducted in February 2021 using a standard version of the 4Sight M sensor on the runway of an airport in Byron, California, in order to isolate targets to better measure and calibrate AEye’s performance.

The 4Sight M sensor was placed at one end of a runway, and a Chevy Bolt and Mercedes-Benz Sprinter Van were placed at the other end, 1,018m away. At this distance, iDAR was able to put more than 50 points on the van, and 39 points on the Bolt. A resolution test saw a 1m2 18% reflectivity target placed 200m away from the sensor. VSI was able to validate that the AEye sensor, with over 175 points on the target, vastly exceeded the metric of 1,600 points per square degree.

A windshield sample was also placed in front of the 4Sight M sensor, with an 18% target placed at a distance of 100m. Various angles of incident were taken, ranging from 0° (parallel to the sensor) to 70°. The same scene was analyzed before and after the windshield glass was placed in front, with no observable impact on performance.

A full VSI report documents AEye’s lidar system achieving breakthrough capabilities in long-range, high-resolution performance and safety required for automotive and trucking highway autonomy.

“The tests delivered impressive results,” said Phil Magney, founder and president at VSI Labs. “We monitored the lidar performance tests and verified that in the range test, two vehicles were clearly identifiable and visible at over 1,000m (1km) with dozens of detections on each. We were also able to verify that AEye’s lidar system delivers 1,600 points per degree and delivers scan rates of greater than 200Hz at full frame. While these are certainly industry-leading performance metrics, we were also able to validate that the 4Sight M sensor, when placed behind a windshield at any angle of incident, did not significantly impact performance. This opens up new possibilities for packaging and placement that we haven’t seen before.”

“At AEye, we set out to create low-cost and high-performance sensing systems, driven by artificial intelligence, that would exceed the capabilities of the human visual cortex,” added Luis Dussan founder, president and CTO of AEye. “By leveraging principles from automated targeting systems and biomimicry, we designed deterministic artificial intelligence sensing systems that redefine traditional lidar performance metrics, while adhering to automotive functional safety standards and delivering the advanced performance required to address the most challenging situations. Our extremely long-range performance both ensures the highest levels of safety and enables new features like highway autopilot that trucking and automotive OEMs desire.”

Active sensing

AEye’s iDAR is a proprietary, intelligent, low-cost lidar that uses active sensing to deliver industry-leading performance and address the most difficult challenges facing autonomous driving while meeting automotive functional safety requirements, according to the company.

Traditional sensing systems passively collect data, while AEye’s active lidar scans the entire scene, while intelligently focusing on what matters in order to enable safer, smarter and faster decisions in complex scenarios. As a result, AEye says its lidar is unique in enabling higher levels of autonomous functionality (SAE L2-L5) at the optimal performance, power and price.

AEye says its patented agile bi-static architecture allows for more flexible mounting locations, including the roof, grill and behind the windshield, with the software optimized depending on the placement. This gives OEMs complete flexibility in implementing sensors within their current design, without changing the aerodynamics of the vehicle.

“As impressive as these performance metrics are, what they enable is even more impressive,” said automated trucking industry technology expert Richard Bishop. “The performance of AEye’s 4Sight sensor will help address critical challenges, such as identifying potholes, stationary road debris or stalled vehicles in time to change lanes, or gaining clear visibility to on/off ramps beyond 300m to ensure safe ingress and egress on freeways. These are game-changers for the trucking industry.”

Software focus appeals to Tier 1 partners

Based in the San Francisco Bay Area, AEye is backed by financial investors including Kleiner Perkins and Taiwania Capital, as well as GM Ventures, Continental AG, Hella Ventures, LG Electronics, Subaru-SBI, Pegasus Ventures (Aisin), Intel Capital, SK Hynix and Airbus Ventures.

“We are more software-oriented than any other lidar company out there,” asserted Stephen Lambright, AEye’s chief marketing officer, during a telephone call with Autonomous Vehicle International. “As such our system is very software configurable – and this is our business model, which is Tier 1 focused. We have partners such as Continental, Hella, Intel and LG, and one of the reasons they like to work with us is that with one manufacturing line, they can build a sensor. But they can configure that sensor using our software to apply any number of different applications, which gives them the ability to be very flexible in how they deploy our technology and deliver a solution that meets each OEM customer’s unique needs. It’s not a one-size-fits-all approach. And when we say it’s software configurable, we can change everything from something very basic, like the field of view, to something much more specific around applying what we refer to as deterministic detection logic, which is basically being able to apply it to a point on a detect within a frame.”

Despite such versatility, Lambright said he expects iDAR to still be competitively priced: “With our Tier 1 partners, we aim to meet their expectations of having a sensor for around US$1,000.”

AEye iDAR and 4Sight M sensor – VSI test results:

-

Range: Greater than 1,000m (1km) on a variety of vehicles, while maintaining a 10Hz Scan Rate (10 frames per second). By delivering more than 4x the distance and 5x the number of detects of conventional lidar, AEye’s system provides unique stopping and avoidance capabilities at highway speeds.

-

Resolution: 1,600 points per square degree on any object across the Field of View (FOV). Delivering ultra-high resolution enables vehicles to quickly and accurately identify and classify threats, especially small objects. Capturing 5x the pre-classification attributes of conventional lidar supports faster and more accurate perception and path control.

-

Speed: Achieves greater than 200Hz scan rate (200 frames per second) for full frame and Field of View (FOV). By scanning at 10x-20x the speed of conventional lidar, AEye’s system provides a unique ability to scan lateral entry from pedestrians or vehicles, and improves the accuracy and consistency of object tracking.

-

Sensor integration Flexibility: Mounted behind first surfaces, including the windshield, with less than 10% observable degradation in performance. The ability to place the sensor behind first surfaces, such as windshield or grill, with minimal performance impact gives OEMs complete flexibility in implementing sensors within their designs without compromising aesthetics or changing the aerodynamics of the vehicle.