Kyocera has released a technical paper investigating the importance and application of varistors in ensuring the reliability and thus safety of ADAS systems.

The paper highlights that the keystone technology for automotive data transfer has to date been automotive Ethernet. Unlike traditional Ethernet used in terrestrial computer networks, the automotive variant uses a single twisted pair for transmission and reception (Bar-Niv).

Defined by the IEEE 802.3 specification, automotive Ethernet is slated to reach data rates exceeding 10Gb/S and serves to connect numerous vehicle subsystems, including those required for ADAS. However, issues such as transient voltage spikes and electrostatic discharge (ESD) can prove problematic for data systems in automotive environments compared to other applications.

Alternator spikes, accessory motor field collapse, solenoid actuation and a host of other noise sources necessitate a much higher tolerance standard for automotive circuits. These requirements are tightly controlled and tested through such regulatory standards as AEC-Q200, ISO-7637, and ISO-10605, to name a few.

One of the most effective techniques for handling electrical surges is the generous application of varistors on power and data lines. This is especially critical in ADAS systems and the associated Ethernet subsystem since any failure directly correlates to the vehicle’s overall safety.

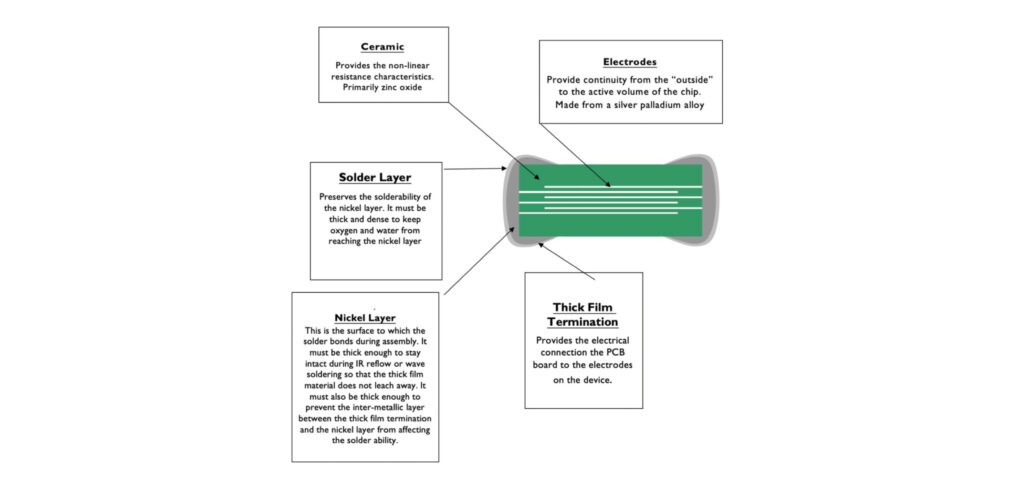

A varistor, or ‘voltage dependent resistor’, works by dramatically reducing its resistance when the applied voltage exceeds a defined threshold. When placed between an electrical conductor and ground, any voltage spikes will be dissipated to ground, thus protecting all downstream components. The technical paper looks at the characteristics and performance of a variety of miniature multi-layer varistors (MLVs) within the context of ADAS system design.

The full technical paper can be found here.