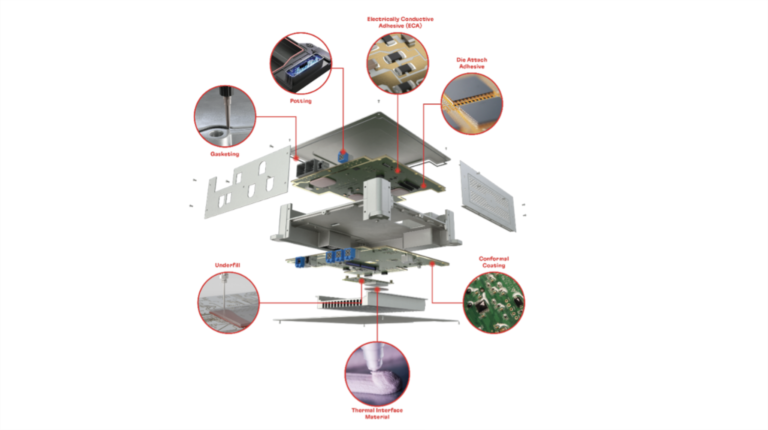

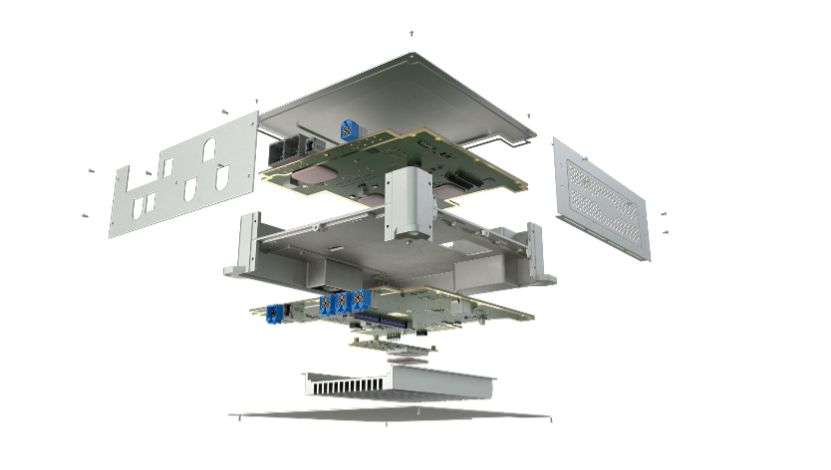

In the evolving landscape of automotive technology, vehicle domain controllers (VDCs) have become central to managing complex electrical and electronic systems in modern vehicles. These controllers consolidate functions across multiple electronic control units (ECUs) into a single, centralized computer. As a result, the number of ECUs needed in a vehicle is reduced, increasing the potential for developmental cost savings, enhanced security and improved design efficiency.

Henkel, a global leader in adhesive technologies and material solutions, has developed a range of innovative materials specifically designed to optimize the performance of vehicle domain controllers.

Enhanced thermal management

As VDCs require increased computing power, more sophisticated thermal management solutions are needed to prevent overheating, which can damage sensitive components and lead to system failures. In fact, according to the Arrhenius equation, for every 10°C increase in operation temperature, the life of a component decreases by half – making thermal management essential to long-term durability and performance.

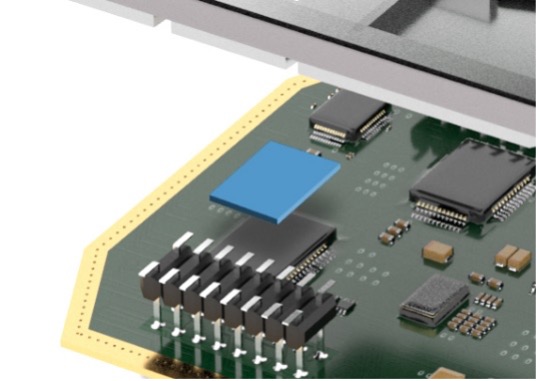

Henkel’s advanced thermal interface materials (TIMs) are engineered to efficiently dissipate heat from the VDC’s components. These materials ensure that the temperature of the controller remains within optimal operational limits, expanding lifespan and preventing performance degradation.

Electromagnetic interference (EMI) shielding

Henkel offers advanced materials for electromagnetic interference (EMI) shielding, which are critical for ensuring the reliable operation of vehicle domain controllers (VDCs) for ADAS sensors. EMI is a significant concern as vehicles increasingly rely on complex electrical systems, including sensors, controllers and communication networks. These systems must operate without interference from external electromagnetic sources and without interfering with other systems within the vehicle. Henkel’s EMI shielding materials are designed to protect VDCs from these challenges by minimizing signal disruption and maintaining the integrity of the vehicle’s electrical components.

Increased reliability and durability

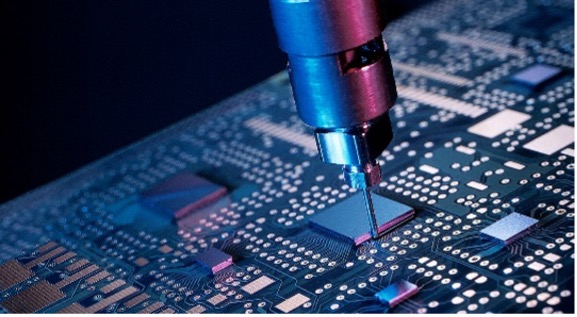

Underfill materials, applied beneath semiconductor chips and other sensitive components, provide mechanical support and prevent damage due to thermal cycling, vibrations and mechanical stresses that can reduce the performance and functionality of VDCs while lowering the potential for repair. Henkel’s underfill solutions effectively fill the gaps between the chip and the substrate, ensuring uniform distribution of thermal and mechanical forces. This helps reduce the risk of solder joint failure, enhances thermal dissipation and protects the components from moisture and contaminants.

Effective sealing

Henkel’s gasketing solutions ensure effective sealing, protection and performance in demanding automotive environments. Gasketing materials, such as Henkel’s Loctite sealants and gasketing compounds, are designed to create reliable seals between components, preventing the ingress of moisture, dust, dirt and chemicals that could compromise the VDC’s functionality. These materials are particularly valuable in protecting sensitive electronic components from external contaminants and environmental factors, including vibration and temperature fluctuations.

Protection from wear and damage

Potting solutions for VDCs provide protection from dust, moisture and other contaminants that could cause damage or potential failure.

Vehicle domain controllers are likely to manage almost all vehicle tasks in the years ahead. As additional VDCs are introduced to enable more centralized operations, material solutions to manage performance and durability play an increasingly important role. Henkel offers a broad range of materials for advanced vehicle electronic components from our Loctite and Bergquist brands to optimize heat, improve durability and lifespan, ensure reliability, prevent electromagnetic interference and more.

Request a consultation with Henkel to learn more.